Difference between MBR and MBBR

Key Difference: Membrane bioreactor (MBR) is a process used for the separation of the solid and liquid phases by use of membranes like micro-filtration or ultra-filtration. On the other hand, moving bed bioreactor (MBBR) uses thousands of biofilm carriers that operate in a mixed motion with a setup containing aerated wastewater.

MBR (Membrane bioreactor) technology was initially developed in the late 60’s, and it gained momentum from early 1990’s. This technology is primarily referred for the treatment of wastewater. It is a combination of a membrane process like micro-filtration or ultra-filtration with a suspended growth bioreactor.

A membrane technology uses activated sludge treatment combined with a separation of the sludge by micro or ultra filtration membranes. These membranes have pore sizes ranging form 10 nm to 0.5 µm. These pores help to produce a particle free effluent. It can also operate at the higher sludge concentrations that are typically up to 20 g/L.

A membrane technology uses activated sludge treatment combined with a separation of the sludge by micro or ultra filtration membranes. These membranes have pore sizes ranging form 10 nm to 0.5 µm. These pores help to produce a particle free effluent. It can also operate at the higher sludge concentrations that are typically up to 20 g/L.

In this process, membranes are immersed in an aeration tank, in direct contact with mixed liquor. Wastewater flows through membrane module and is then pumped (with negative pressure) through a collector to the outlet. Commercially, six membrane separation processes are used- Microfilteration, Ultrafilteration, Nanofilteration, Reverse Osmosis, Dialysis and Electrodialysis. These are classified on the basis of these features:-

- Size of membrane

- Mechanism

- Membrane material and configuration

- Driving forces used for separation.

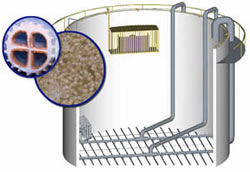

MBBR is also known as moving bed biofilm reactor. It is preferred for the improved reliability and simplified operation than compared to the traditional wastewater treatment systems.

This technology makes use of many (around thousands) of polyethylene biofilm carriers that operate in a mixed motion within an aerated wastewater treatment basin. The protected area of the biofilm and apt conditions help in growing and thriving of the bacteria culture. An aeration grid is situated at the bottom of the reactor that supplies oxygen to the biofilm. It helps in keeping the biocarriers suspended and they get completely mixed with the reactor. The biofilm on the carriers break down the wastewater and the treated water comes out through a grid or  sieve in which the biocarriers are retained.

sieve in which the biocarriers are retained.

These systems can also be used in combination with conventional activated sludge system or as a hybrid system. The reactors are also often equipped with special spray nozzles which help in preventing foam. Some of the key features are listed below:-

1. Robust

2. Efficient

3. Compact

4. Cost effectible

5. Flexible

6. Easy operation

Thus, both use different technologies for the filtration processes. Some of the differences are listed below:-

|

|

MBR |

MBBR |

|

Full form |

Membrane bioreactor |

Moving bed biofilm reactor |

|

Definition |

A combination of membranes is used for the separation and retention of solids. |

Biofilm growing on surface of moving carrier is used for the water treatment. |

|

Operation |

Complicated |

Easy |

|

Personnel cost |

High |

Low |

|

Consumables cost |

High |

No |

|

Application |

Biological wastewater treatment, wastewater recycling, wastewater treatment plant upgrade: expand capacity, upgrade facilities within existing plant area to meet more stringent discharge limits. |

Food and beverage plants, steel mills, oil refineries, petrochemicals, chemical plants, paper mills and any industries requiring wastewater treatment for BOD removal, nitrification and denitrification. |

Image Courtesy: brightwaterfli.com, cleanwatertech.com

Add new comment