Difference Between Drying and Dehydration

Key Difference: Removal of water is the primary motivation behind both the terms 'drying' and 'dehydration'.The term drying is commonly utilized in cases where water is removed utilizing the impact of non-customary vitality sources like sun and wind. Whereas dehydration means the process of removal of moisture by the application of artificial heat under controlled conditions of temperature, humidity and air flow.

Drying

Drying

Drying is a mass transfer process comprising of the expulsion of water or another solvent by evaporation from a solid, semi-solid or liquid. This procedure is regularly utilized as the last step before selling or packaging products. To be considered "dried", the final products should be solid, as a consistent sheet (e.g., paper), long pieces (e.g., wood), particles (e.g., oat grains or corn flakes) or powder (e.g., sand, salt, washing powder, milk powder). A source of heat and an agent to remove the vapor produced by the process are often involved. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water.

Different types of methods used for drying are as follows:

- Air Drying: Air drying is a generally utilized and dependable drying process, which can be ordinarily seen if there should arise an occurrence of wide utilization of air-dried natural products in most areas of food production.

For food products, there are two different methods of air drying:

- Sun Drying: In numerous nations with high measures of daylight and moderately low humidity, raw materials are generally dried specifically noticeable all around. The naturally raw materials are exposed out on a surface for a few days, amid which time they are turned over numerous occasions in the sun. This normal procedure expels water from the regular raw materials, forcefully decreasing their water content. The measure of dampness that is still held after this procedure differs as indicated by item type and customer request. Sun drying is a simple and cost-effective natural process that is utilized particularly every now and again for Mediterranean herbs,spices and dried fruits.

- Industrial Air Drying:As opposed to sun drying, industrial air drying with its belt dryers and tray dryers allows for more precise control of the drying procedure.. Through this automated procedure, a stream of hot air is utilized to expel dampness very equally from the raw materials. With this treatment, the raw materials gain a long shelf life without the addition of preservatives.

- Freeze Drying: Freeze-drying is a technique by which natural raw materials might be preserved without the use of preservatives. The procedure secures not just the colour and cell structure of the item, yet additionally, rather than the usual drying techniques, it guarantees better maintenance of substance and flavor components.

2. Drum Drying: For pulpy or pasty products, drum drying (otherwise called roller drying) is the chosen method of drying. Amid this procedure, a thin film of the item is spread over a rotating drum that is warmed from inside. The water in the material dissipates inside a couple of minutes, after which the dried item can be expelled from the drum surface.

Applications of drying

- Food: Foods are dried to restrain microbial advancement and quality decay. Be that as it may, the degree of drying relies upon item end-use.

- Non-food products: Among non-food products, a portion of those that require significant drying are wood (as a major aspect of timber handling), paper, flax, and washing powder. The initial two, owing to their organic origins, may develop mold if insufficiently dried. Another advantage of drying is a decrease in volume and weight.

- Sludges and faecal materials from sanitation processes:In the region of sanitation, drying of sewage ooze from sewage treatment plants, faecal sludge or defecation gathered in urine-diverting dry toilets (UDDT) is a typical strategy to accomplish pathogen kill, as pathogens can just endure a specific dryness level. Moreover, drying is required as a procedure step if the excreta-based materials are intended to be incinerated.

Dehydration

Dehydration

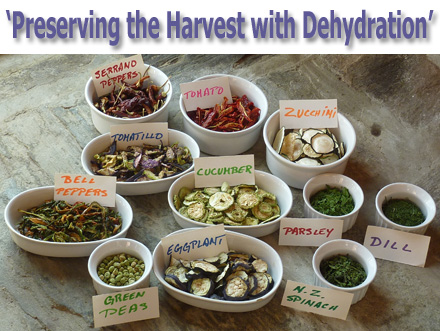

Dehydration means the process of removal of moisture by the application of artificial heat under controlled conditions of temperature, humidity and air flow.Dehydrating food is one of the oldest and easiest methods of food preservation. Lack of hydration makes the food smaller and lighter, making them perfect for hiking, climbing, and outdoors. The extra advantage is no need of refrigeration.

The concept of dehydration was developed in France in 1795. Present day lack of hydration procedures have been to a great extent animated by the advantage’s dehydration gives in compactness; dehydrated food has about 1/15 the bulk of the original or reconstituted product. The need to transport expansive shipments of food over extensive distances during World War II played an important role in providing much of the stimulusto for perfect dehydration processes.

Dehydration equipments differs in shape with various food products and includes tunnel driers, kiln driers, cabinet driers, vacuum driers, and other forms.Equipments with minimal hardware appropriate for home utilize are also available. The main aim of the design is to abbreviate the drying time, which helps retain the essential character of the food item.

Applications of drying

Dairy industry primarily makes use of dehydrated food, producing quantities of whole milk, skim milk, buttermilk, and eggs. Many dairy products are spray dried—that is, atomized into a fine mist that is brought into contact with hot air, causing an almost instant removal of moisture content.

|

|

Drying |

Dehydration |

|

Definition |

Process of removal of water using the influence of non-conventional energy sources like sun and wind. |

Process of removal of moisture by the application of artificial heat under controlled conditions of temperature, humidity and air flow. |

|

Methods |

|

|

|

Primary Application |

|

|

Image Courtesy:preparednessadvice.com,penbaypilot.com

Add new comment